Simple assembly

Setup could not be any easier

- Avoid contact between the construction elements.

- Ensure that the subsoil is firm and has a good load bearing capacity. For applications that require an official technical approval, a static sufficiently measured, bearing and walkable foundation as a support for EasyDeck® boards /subconstructions is also required.

- When using metric screws, all of the holes should be pre-drilled so that the part that is to be fixed in place, is 2 mm larger and the retaining drillhole is exactly 0.5 mm smaller than the diameter of the screw!

- Observe the minimum clearances of the expansion joints so that the construction can expand without force if necessary and a sufficient amount of ventilation from underneath is ensured.

- Cutting the longitudinal side of the boards may result in board offset.

- Do not lash down or brace the deck during construction.

- Rod-shaped components that are to be screwed onto a rigid substructure, always have the fixed point in the centre and floating outwards so that thermal expansion and an expansion due to an absorption of water can be compensated for.

- Distance between the deck board and all fixed components: 20 mm

- Do not fill cavity spaces between the level surface of the gravel and subconstruction elements.

- Recommended minimum gradient of 2 % in the longitudinal direction of the boards.

- Maximum deck board protrusion over the last subconstruction is 50 mm.

- Production-related dimension tolerances regarding length, width and thickness are to be taken into account during assembly and the dimensions on the construction must be examined once again.

- Choose the material versions for punched parts, such as standard steel or stainless steel for clips, to suit your structural conditions.

- The boards are to be cut off at right angles and then to chamfer.

- Wind load must be considered as a lifting load in the construction when designing a terrace.

- Predrill all of the holes before screwing it in place.

Easy processing of

the material.

Simple assembly for all structure types

We have created an easy-care and resistant material. Products made of GCC HOLZart can be processed just like wood. Common woodworking tools can shape the material as desired by sawing, drilling, sanding, or planing. GCC HARZart is denser and harder due to its share of synthetic resins, causing greater tool wear. This is why we do not recommend full surface machining such as planing, brushing, or sanding.

We want you to enjoy your new terrace for a long time. Only use original EasyDeck® parts and observe our processing recommendations to ensure that our warranty does not become void. Coordination with the manufacturer must take place and respective approval must be obtained in the event of special structures that deviate from these processing recommendations or the online planner in order for any potential warranty claims to be accepted.

Simply pay attention to the laying direction

Lay all of the boards in the same direction in order to obtain a homogeneous surface effect. This direction is shown by an arrow in the board groove or on a label on the board. Mix the boards prior to laying. This allows the slight differences in the colour of the boards to emphasise the natural appearance.

Mechanical characteristics of the boards and floor panel

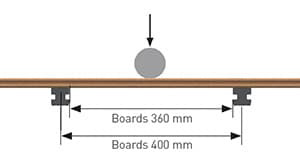

| Three-point bending | Boards |

|---|---|

| Support clearance: | 360 mm |

| Test speed: | 20 mm/min |

| Breaking load: | 3.200 N* |

3200 N corresponds to ≈ 320 kg/board with a maximal clearance

of 400 mm from the substructure.

Production-related dimension tolerances of EasyDeck® boards and floor panel

| Specification | Tolerance field | Dimension | Measurement point | Permitted dimension change after water absorption* guaranteed values |

Remark | ||

|---|---|---|---|---|---|---|---|

| Profile length | 3000 / 4000 / 5000 mm | ±0,0/+10,0mm | Length | Maximum value | Board length 3000 mm Board length 4000 mm Board length 5000 mm |

≤ 9,0 mm ≤ 12,0 mm (≤ 3 mm/m) ≤ 15,0 mm |

Distance from other fixed components, min. 20 mm |

| Profile width | 130/138/145/163/ 193/245mm | –2,0/+1,0mm | Width max. 245 mm | Board, centre | max. ≤ 1,2 mm | ||

| Profile thickness | 16/19/25mm | –1,0/+1,0mm | Thickness max. 19 mm | Board, centre | max. ≤ 0,5 mm |

* In the event of exposure to outdoor weathering and construction executed in accordance with the construction manual

Assembly on concrete edge stones

In accordance with good practice and constructive wood preservation principles, we recommend to lay the boards with a minimum gradient of 2% in the longitudinal direction. As a result, the water can flow away, water logging and building damage is prevented and water stains are minimised.

Preparation of the subsurface

1. Establish a soil formation

Establish a soil formation with a gradient of 4%.

2. Create a ballast bed

Whilst ensuring that it protrudes by 500 mm around the circumference of the terrace, create a ballast bed (including drainage) with a 2% gradient. Apply fine grit to the ballast bed with a 2% gradient.

Assembly of the subconstruction

3. Lay the concrete edge stones

Lay the concrete edge stones (100 x 25 x 5 cm) on a gradient gravel bed with a centre distance of 500 mm.

4. Distribute the construction beams

Equally space the construction beams (40 x 40 mm) transversely to the concrete edge stones (the groove is at the bottom), ensuring that there is a protrusion of 50 mm on the end face (see detail 8). Position two beams at the beginning and two at the end (axial dimension: 160 mm). Place 10 mm rubber pads underneath the construction beam and compensate for any gradient differences with additional rubber pads. Screw the construction beams around the entire edge of the terrace and the beams that the retaining band is mounted on, to the concrete slab. When laying the terrace herringbone style, the construction beams need to be screwed to the concrete slabs that are positioned underneath the beginning and end of the board.

5. Offset positioning

If the terrace should be more than 3 m wide, the ends of the construction beam are always to be positioned offset and connected using the connecting clamp. The connecting clamp makes it possible to create terraces that are larger than 12 x 12 m without the requirement for structural expansion joints.

6. Cut the connecting clamp

Cut the connecting clamp to 250 mm so that the beam joints are joined to each other and then screw tightly on one side (clearance of the joints: 10 mm).

7. Saw the connection clamp

Saw the connecting clamp to a width of 20 mm and a depth of 10 mm at the outer construction beam so that the rhombus profile can be used as a closing strip in the area of the screwed connection. The butt joint of the rhombus profile accommodate the butt joints of the subconstruction.

8. Additional piece of construction beam

8. Mount an additional piece of construction beam piece (length 320 mm) for butt joints of the rhombus profiles in the direction of the boards. The butt joint of the rhombus profiles will accommodate the butt joint of the boards with the boards laid in herringbone style. Screws are placed in the double mount construction beams.

9. Adhere retaining band

Fix the retaining band to a construction beam that is located in the centre underneath the board. When using the Distanz Fix when laying herringbone style, the retaining band has to be fixed to each of the construction beams.

Assembly of the boards with clip

10. Chamfer cut edges

Chamfer the cut edges of the boards.

11. Place an edge clip

Place an edge clip at the beginning of the face of the construction beam so that it is flush with the beam, pre-drill to a depth of 3 mm and loosely fix in place using a screw (do not tighten yet).

12. Fasten boards with clip

Push the first board onto the positioned edge clip. Use the clip for the following boards, pre-drill to a depth of 3 mm and loosely fix it to the construction beam using the enclosed screws. Now push the next board against it until the clip is positioned against the groove. Tighten the clip applying the average torque after approx. 5 rows of boards have been laid. Repeat this until the last board but one has been layed.

13. Cut the construction beams

After the penultimate board, calculate the width that is required for the final board and cut the construction beams so that they are flush. The construction beam is to protrude 10 mm over the edge of the final board so that the edge clip can be positioned as an end fastener.

14. Final board

Position the final board and fix the edge clip in place. Pre-drill a hole for the screw and screw in place applying an average torque.

15. Cut the boards

Cut the boards to length at a right-angle at the face edge, ensuring that there is a protrusion on 15 mm. Maximum board protrusion: 50 mm. Chamfer the cut edges.

Mounting the rhombus profiles as closing strips

16. Front side closing strip

Leave a minimum clearance of 15 mm between the rhombus profile and the surface of the ground.

17. Parallel closing strip

Screw the rhombus profiles maximum 60 mm from the ends and maximum 400 mm from each other and pre-drill true to the principles. When laying parallel to the boards, screw on using M8 x 40 mm screws so that they are flush with the end edge

of the construction beam. Act in accordance with Detail 8 as regards butt joints.

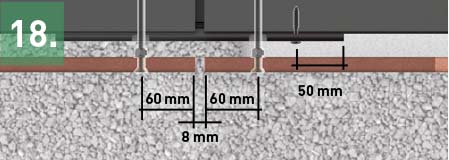

18. Cut the lenght of boards

When mounting at the face towards the boards, screw on using M8 x 80 mm fastening screws and use the corresponding nut as a spacer and in order to fix in place.

Item overview for assembly on concrete edge stones

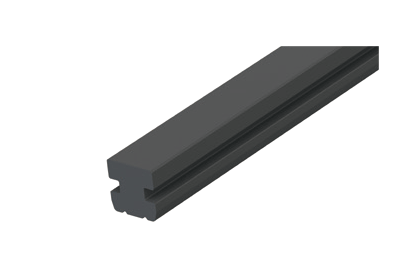

Construction beam 40 x 40 mm

Fastening screw for subconstruction 7,5 x 92 mm

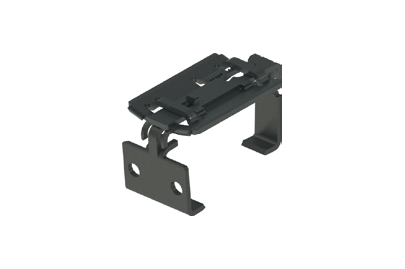

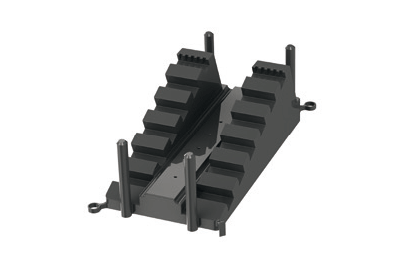

Connecting clamp

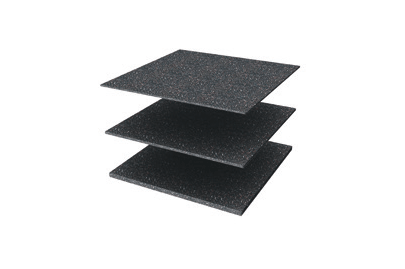

Rubber pad 100 x 60 x 20 mm 100 x 60 x 10 mm 100 x 60 x 3 mm

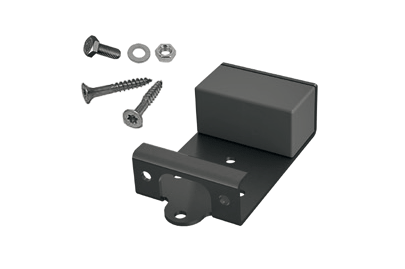

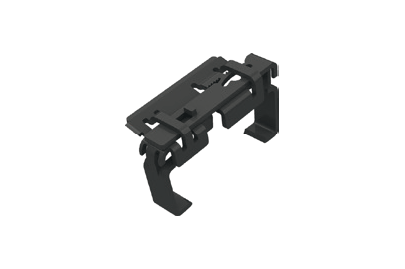

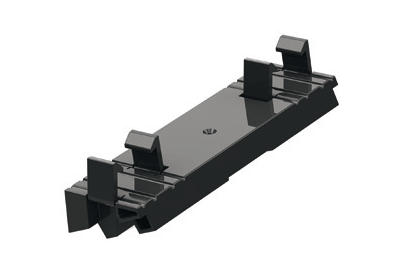

Locking clamp (one-piece) incl. screws

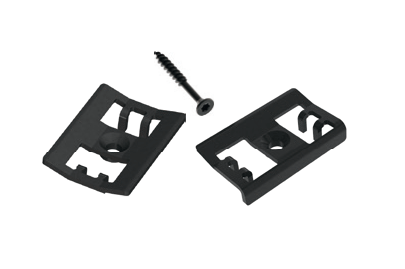

Edge clamp

(two-piece)

Groove bridge

Clip & edge clip incl. screws

M6 x 40 mm screw in order to screw short deck board sections

Distanz Fix for the creation of a heading joint (5 mm/8 mm) incl. screws

Arretier Fix for the height locking of the butt joints

Retaining band, self-adhesive

M8 x 40 mm fastening screw for the rhombus profile as a closing strip

M8 x 80 mm fastening screw for the rhombus profile as a closing strip

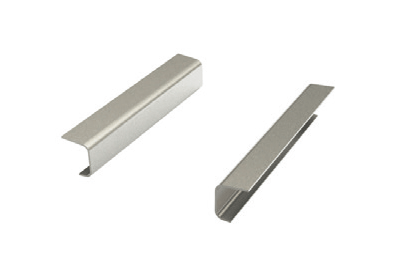

Rhombus profile as a closing strip 81 x 20,5 x 4200 mm

Rhombus profiles have a matted surface and differ from the deck board colours.

Fokus Chocolate Black

for deck boards Glacier , Terra Trend Terra, Relief R24 Fokus Chocolate Black

Fokus Brown

for deck boards Dolomit Brown and Fokus Brown

Fokus Grey

for deck boards Glacier Graphit, Dolomit Grey and Fokus Grey, Trend Graphit, RELIEF R24 Fokus Grey

Green Black

for deck board Dolomit Green Black

Sandy Brown

for deck board Dolomit Sandy Brown

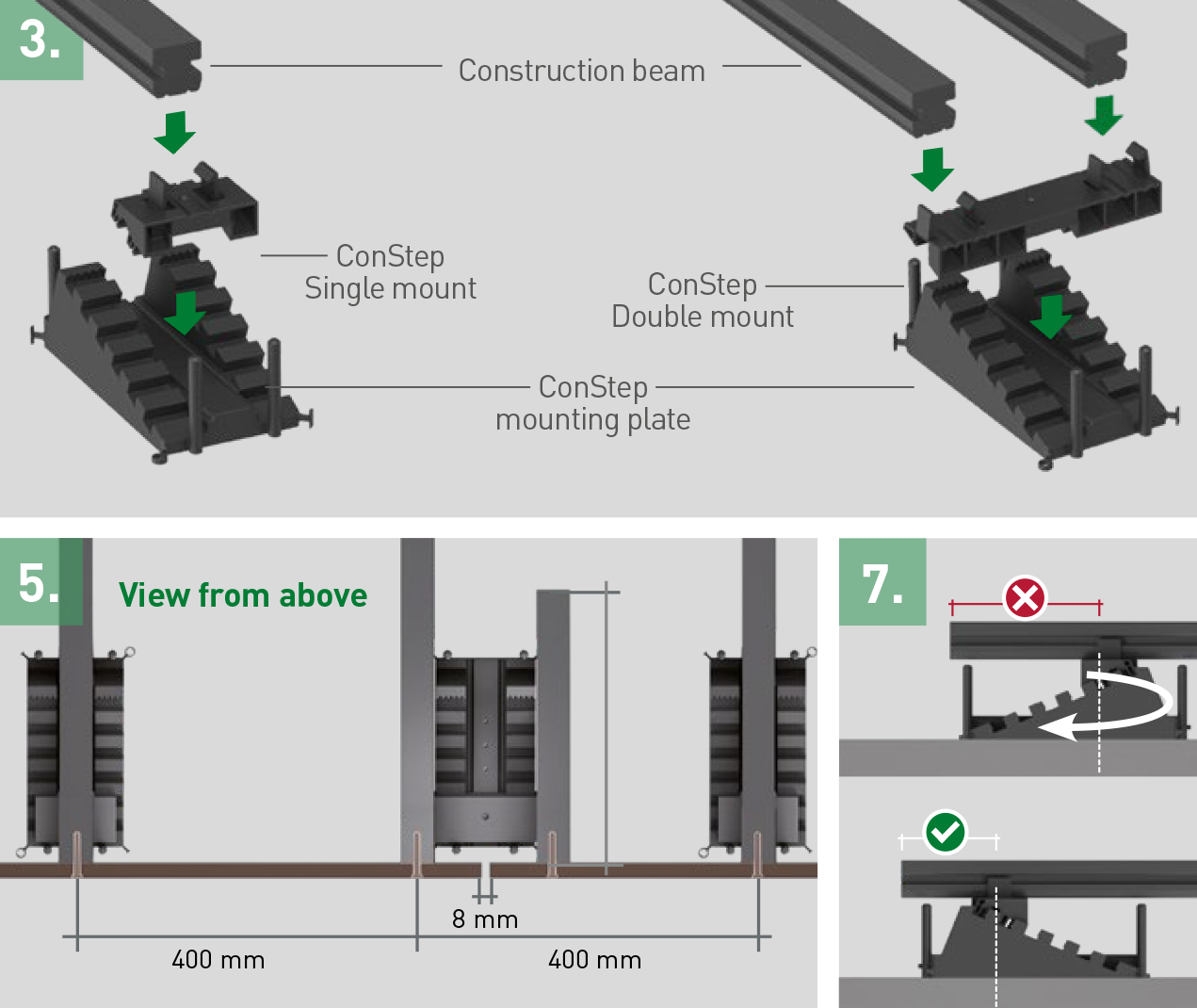

Assembly with ConStep system

Our sophisticated ConStep system is the best sub-construction for your EasyDeck®

terrace. The system components impress with their lightness, variable installation heights and ease in terms of laying. Single and double mounts are clicked into the ConStep mounting plate and form the base of the construction beams which will be applied on top.

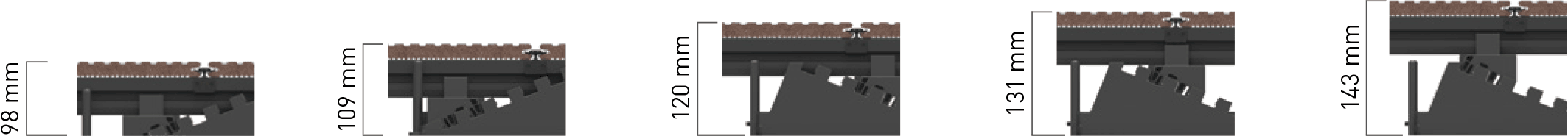

Easily implemented variable installation heights

Our patented click system allows construction heights of between 98-143 mm (in steps) to be easily implemented.

Preparation of the subsurface

1. Establish a soil formation

Establish a soil formation with a gradient of 4%.

2. Create a ballast bed

Whilst ensuring that it protrudes by 500 mm around the circumference of the terrace, create a ballast bed (including drainage) with a 2% gradient. Apply fine grit to the ballast bed with a gradient of 2%.

Assembly of the ConStep plates

3. ConStep mounting plate

In all of the ConStep mounting plate, click in the single and double mounts to the same height and centrally bond into place with a piece of retaining tape.

4. Distance to the house wall

Position the ConStep panel with double mount at a distance of 80 mm to the house wall and a maximum alignment of 500 mm to the next ConStep panel with double mount.

5. Dimension between axes

Position the ConStep panel with single mount with max. 400 mm dimension between axes in the next row.

6. ConStep double mount

Conclude the end of the deck using a further ConStep double mount. Click the sub-construction into place.

7. Minimise protrusions

Minimise protrusions. In order to do so, turn the ConStep panel where necessary.

8. Reinforce the sub-construction with perforated band

Using the ConStep assembly clip, reinforce the entire sub-construction with perforated band in a crosswise manner.

Assembly of the board with locking clamp

9. Position the edge clamp

Saw into the construction beam from the side from which the boards are to be laid. This must be performed 12 mm from the edge, to a depth of 5 mm and to a width of 2 mm. Position the edge clamp in this groove and, using pliers, fix together with the construction beam and push the board into the edge clamp.

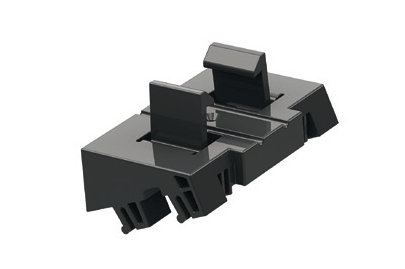

10. Place the locking clamp

Place the locking clamp onto the construction beam, fix into place using pliers and push into the deck board groove. Using the supplied screw, engage the lock lips into every 3rd deck board row on the construction beam.

11. Saw the construction beam to length

After the penultimate board, determine the required width for the last deck board and saw the construction beam to length so that it is flush. In doing so, please note that the construction beam must protrude by 12 mm from the last board (for fixation of the edge clamp).

Assembly of the edge board see items 14 and 15 of

assembly on concrete edge stones

Continue at assembly of the sub-construction

concrete edge stone point 4 to 9.

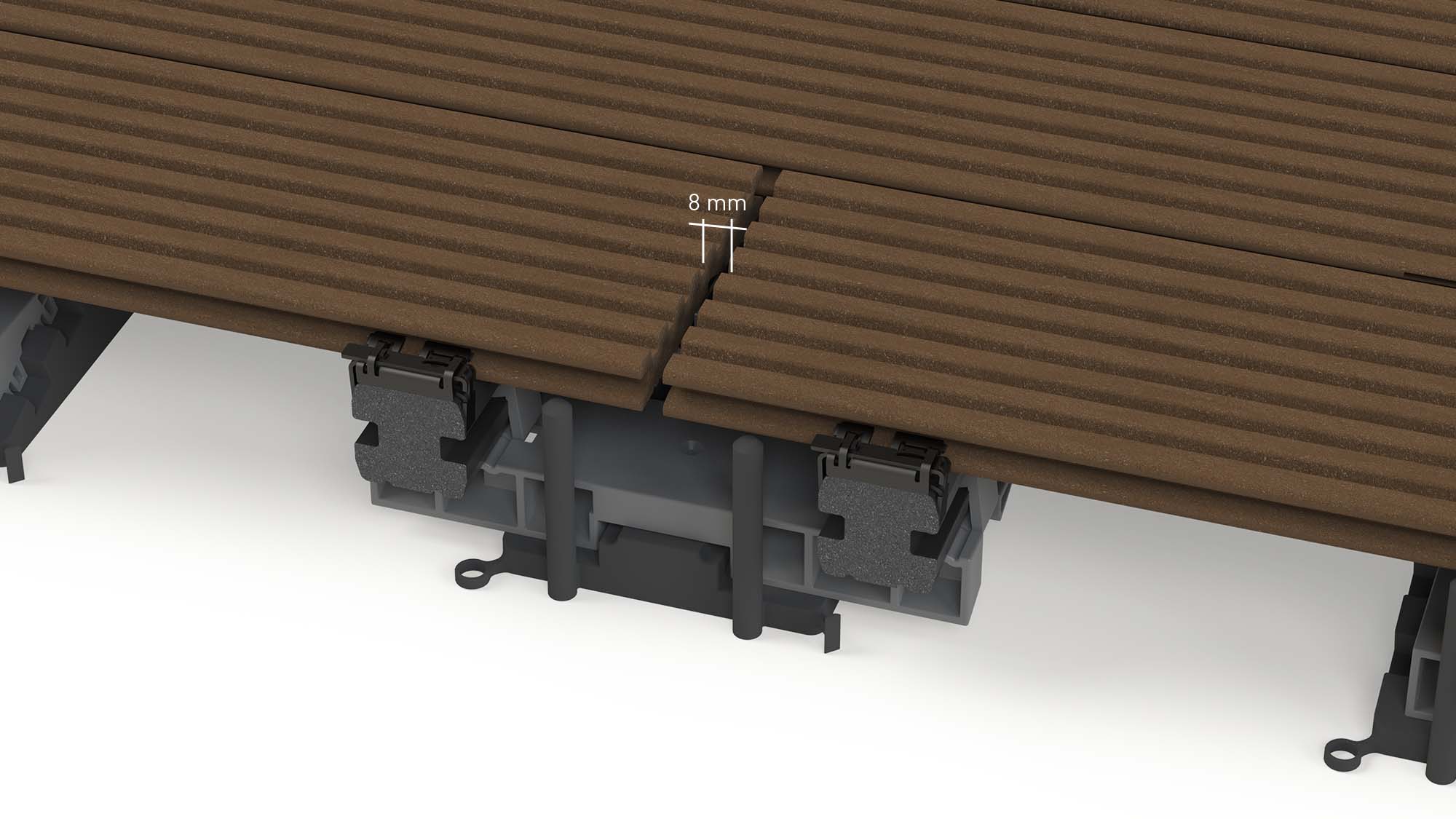

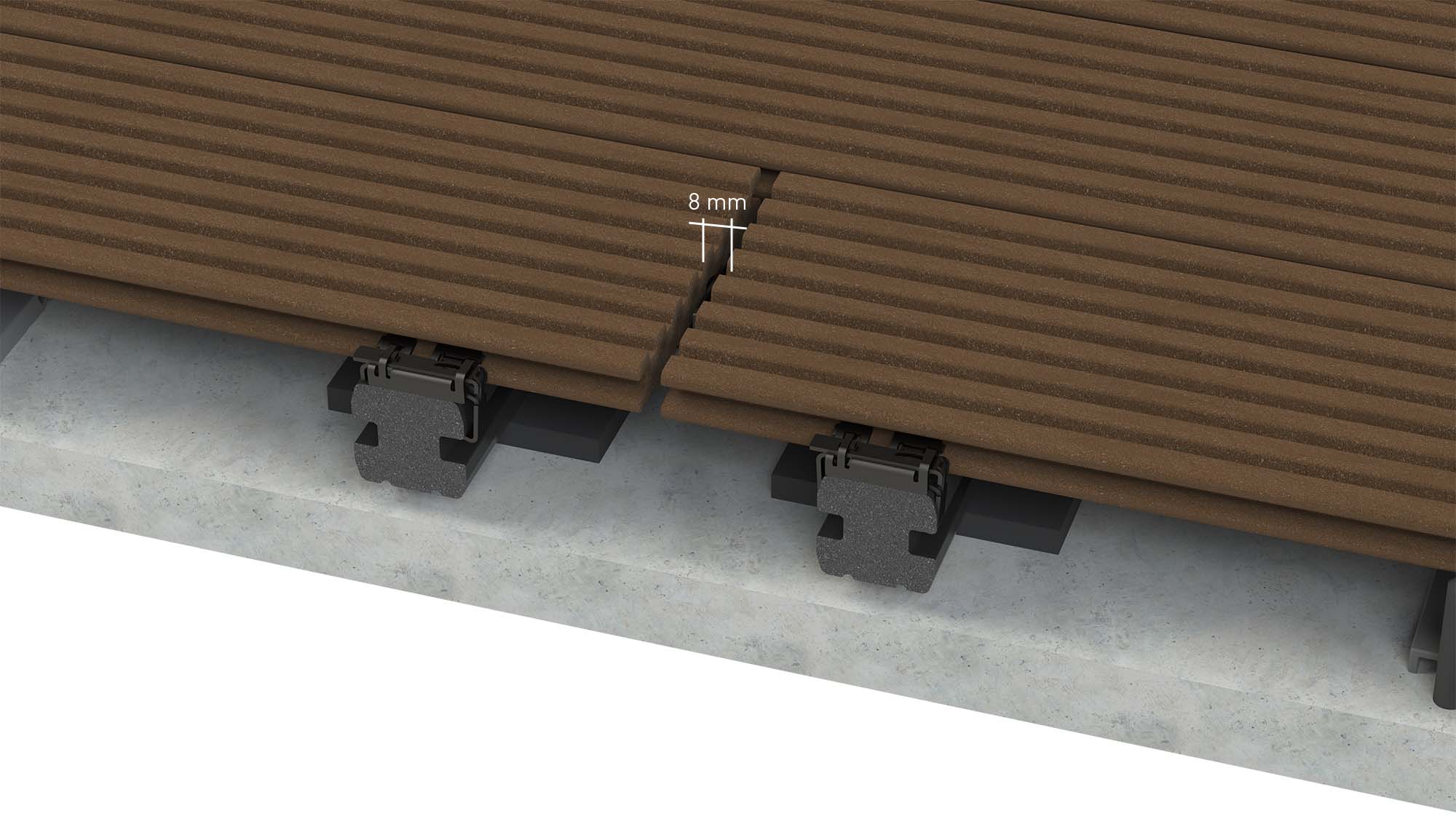

Installation in a brick bond with double subconstruction beam

Clearance between the boards at the end edge: min. 8 mm. Use the Distanz Fix component for an ideal gap appearance. At the joint of two boards, use a construction beam at the start and end of the board respectively. Do not hit on a construction beam.

Assembly with the example of ConStep double mount

Installation using the example of concrete kerbstone

Additional items for assembly with the ConStep system

ConStep mounting plate

ConStep double mount

ConStep single mount

ConStep Rubber pad

300 x 300 x 10 mm

300 x 300 x 5 mm

300 x 300 x 3 mm

Perforated band